SFM-3260 Sprayformed Super Abrasion Resistant High Speed Steel | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Composition(%) | C | Cr | Mo | W | Co | V | ||||||||||||||||||||||||||||||||||||||||||||||||||||

2.30 | 4.2 | 7.0 | 6.5 | 10.5 | 6.5 | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Grade: | SFM-3260 (Similar grades:HS 6-7-6-10, W.Nr.1.3241, ASP2060) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Delivery Status: | Soft-annealed ≤HB340, or ready-made tools, UT qualified. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Material feature:

| Super high solidification rate in sprayforming makes the microstructure very fine and homogeneous. Ultra-high-alloyed carbides and nitrides in microns are spheroidal, uniformly distributed in the matrix, facilitating excellent red-hardness, isotropic mechanical properties and good machinability, even better wear resistance and tooling life comparing to similar grade of PM steel. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Applications: | Very high alloyed high speed steel for tools requiring both hot hardness and wear resistance, such as extrusion die, demanding gear cutting tools, broaches, punches, drills, end mills, etc. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product sizes: | Round bar, up to DIA 300 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rectangular bar: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

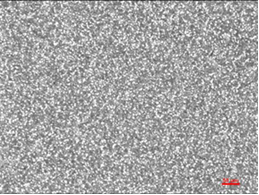

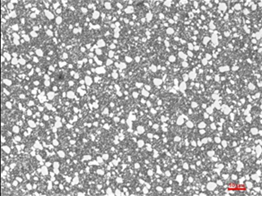

Microstructures: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbide morphology in a sample of DIA 290 mm bar, 100x (L) & 500x (R) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Remarks: Our expert, inventor of SFM Process, will technically support your applications to best benefits. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Company address: 18-A02 of 4th Xingye Road, Guanglong Industry Park, CN-528313 Foshan, China Tel./ Fax: 0757-23316070 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The above data are as reference, which is subject to change by SFM | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||