SFM-3020 Sprayformed High Speed Steel | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Composition(%) | C | Cr | Mo | W | Co | V | ||||||||||||||||||||||||||||||||||||||||||||||||||||

0.90 | 4.20 | 5.00 | 6.40 | - | 1.80 | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Grade: | SFM-3020 (Similar grades:AISI M2 ESR, HS 6-5-2, JIS SKH51, DIN 1.3343) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Delivery Status: | Soft-annealed ≤HB260, or ready-made tools, UT qualified. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Material feature:

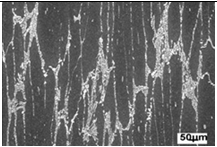

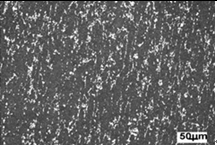

| Super high solidification rate in sprayforming refines the carbide morphology from rough net- works to near-equiaxed, as can be seen from the pictures below, generating better machinability, more isotropic mechanical properties, e.g. impact toughness increases by 70 - 100%. That means usable hardness of the tools can be increased under the same toughness requirement, thus to reach much better wear resistance and tooling life than similar grade of ESR. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Applications: | Basic and universal HSS for various cutting tools: drills, reamers, broaches, milling cutters, saw blades, various knives; punching dies, cold work tools, rolls, etc. Due to its high and isotropic strength and toughness, it is specially suitable for heavy load or large tools. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product sizes: | Round bar, up to DIA 300 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rectangular bar: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Microstructures: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbide morphology in DIA 250 mm bars, 100x, M2 ESR (L), and SFM-3020 (R). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Remarks: Our expert, inventor of SFM Process, will technically support your applications to best benefits. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Company address: 18-A02 of 4th Xingye Road, Guanglong Industry Park, CN-528313 Foshan, China Tel./ Fax: 0757-23316070 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The above data are as reference, which is subject to change by SFM | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||