SFM-2131 Sprayformed Abrasion Resistant Hot-Work Steel | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Composition(%) | C | Si | Mn | Cr | Mo | V | ||||||||||||||||||||||||||||||||||||||||||||||||||||

0.4-0.6 | 0.8-1.2 | 0.3-0.5 | 4.5-5.5 | 0.8-1.8 | 1.0-1.8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Grade: | SFM-2131 (Similar grades:Superior H13 ESR or PM) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Delivery Status: | Soft-annealed or pre-hardened blanks or ready-made tools, UT qualified. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Material feature:

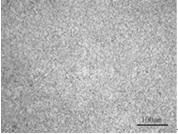

| Super high solidification rate in sprayforming with hot forging makes the microstructure very fine and homogeneous, and tailor designed amount of alloyed carbides and nitrides in microns are uniformly distributed in the matrix, which provide better wear and thermal fatigue resis-tance in hot working than conventional grades. It has better machinability, including polishing and edge-griding properties, and holds hardness better at elevated temperature. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Applications: | High-performance extrusion dies, pressure die casting (PDC) dies, hot-forging dies, precision forging dies, seamless pipe rolling mandrel, components of high strength, high wear resistance and heat resistance, etc. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product sizes: | Round bar, up to DIA 300 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rectangular bar: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

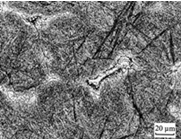

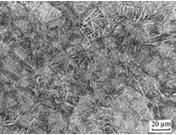

Structure comparison: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

H13 ESR before forging,500X SFM-2131 before forging,500X SFM-2131 forged & annealed,250X | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Remarks: Our expert, inventor of SFM Process, will technically support your applications to best benefits. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Company address: 18-A02 of 4th Xingye Road, Guanglong Industry Park, CN-528313 Foshan, China Tel./ Fax: 0757-23316070 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The above data are as reference, which is subject to change by SFM | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||