SFM-1120 Sprayformed High V and Wear Resistant Cold Work Steel | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Composition(%) | C | Si | Mn | Cr | Mo | V | ||||||||||||||||||||||||||||||||||||||||||||||||||||

2.90 | < 1.0 | < 1.0 | 5.25 | 1.30 | 11.5 | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Grade: | SFM-1120 (Similar grades:CPM12V) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Delivery Status: | Soft-annealed ≤HB280, or ready-made tools, UT qualified. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Material feature:

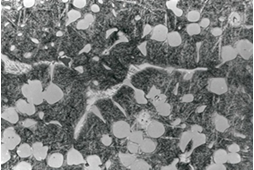

| Super high solidification rate in sprayforming refines the massive carbides into equiaxed and a few microns in size, offering combination of high hardness and toughness,good machinability, and isotropic mechanical properties. Its wear resistance is about 5 times better than D2, even better than its PM conterpart. It microstructure is shown in the picture below. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Applications: | For high abrasion resistant cold work tools or parts, such as metal sheet and paper rotary cutters, crusher wear parts, stamping and punching dies, cold extrusion dies, feeding screw, injection moulding cylinder sleeve, ceramics and powder metallurgy moulds and their reinforcement inserts or strips, quality woodworking tools, etc. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product sizes: | Round bar, up to DIA 300 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rectangular bar: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Microstructures: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbide morphology in DIA 20 mm cast sample, 300x (L), and SFM-1120 300x (R). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Remarks: Our expert, inventor of SFM Process, will technically support your applications to best benefits. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Company address: 18-A02 of 4th Xingye Road, Guanglong Industry Park, CN-528313 Foshan, China Tel./ Fax: 0757-23316070 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The above data are as reference, which is subject to change by SFM | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||